Quality Certification

We achieved IATF16949:2016、ISO14001:2015、ISO 9001:2015 Certification and maintained quality standards. But for us, ISO Certification is just the beginning of the quality process.Our team of Quality Engineers are involved from the beginning of the project, assuring consistency in manufacturing.In-Coming, In-Process, as well as Out of Box quality are measured on a weekly basis in order to improve our manufacturing processes along with those of our suppliers. This data in addition to any customized requested reports, is tracked by product and facility, and communicated to our customer.

Quality Commitment

We rely on the perfect facilities to provide strict quality products and services, completely reliable to meet customer requirements.The systems in place at entities ensure management of appropriate activities during concept development, prototype, and production.

Training

The basis for any continual improvement program.These programs include on-the-job training, statistical process control, design of experiments, and cycle time reduction.

Process Specifications and Operating Procedures

Including process documents、SOP、engineering drawings - must be approved, available to the process control personnel, and fully implemented.

Manufacturing Quality Control Implementation

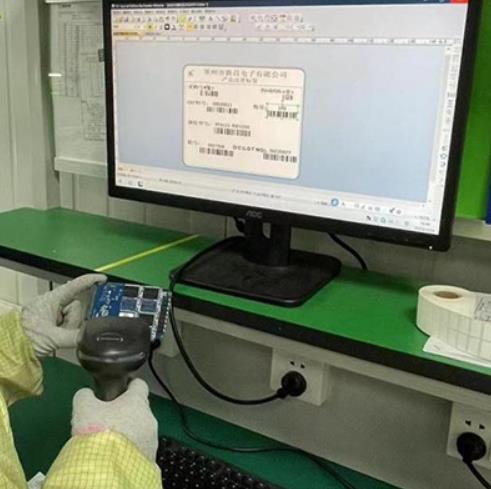

ERP, MES, WMS, ESD and Error Proof System are used in the production process. This is used as a means of tracking critical characteristics of processes and determining control points and methods.We implement methods of SPC, process capabilities, and design of experiments. 100% inspection and visual inspection of the product.

On-Time Delivery

We have barcode management for shipment, which can trace the quality of each batch and deliver the goods on the promised date.Our goal is to reduce cycle time, and improve quality.

Supplier Partnership Program

We work with suppliers to develop and implement their continual improvement programs. This cooperation helps the supplier understand his quality performance .By working with suppliers, we can improve quality, reduce costs, and provide rewards to good suppliers in the form of more business.This helps to stabilize our supply chain and improve quality.

ENGLISH

ENGLISH 简体中文

简体中文